Nissan develops technology to halve recycling cost of rare earths

- Nissan informs that it will continue experimenting with larger-scale facilities, planning to make the process commercially viable in the mid-2020s.

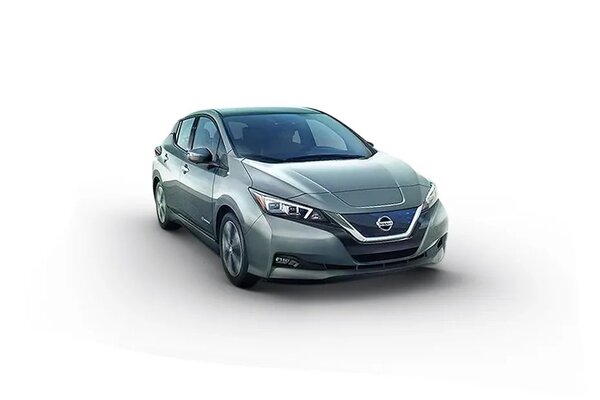

Japan's Nissan Motor Co Ltd has developed a new technology to halve the cost of recycling rare earths used in magnet motors for electric vehicles (EVs), the company said on Friday.

With tension simmering between China and the United States, automakers are trying to reduce their reliance on a key driver of the EV revolution - permanent magnets that power electric engines, as most are made of rare earth metals from China. Automakers are also concerned about huge price swings of the metals and environmental damage in the supply chain.

Also check these Vehicles

Nissan, collaborating with Katsunori Yamaguchi, a professor at Waseda University, established a new recycling technology to recover rare earth compounds in high purity and efficiency without dismantling the motor, which is the conventional way.

Also Read : New Nissan electric mini vehicle will feature instant acceleration, quiet cabin

Permanent magnet motors - using rare earths such as neodymium and dysprosium - naturally have magnetic force. These are at the heart of many electric motors, powering the rotor of the drivetrain. With the new technology in a dry refining method, Nissan melts the rotors in a furnace above 1,400 Celsius, extracts them as an oxide liquid, and then separates them to extract the rare earths.

The new method will shorten the processing time to about 4 hours from 8 hours now and halve the recycling cost, Kazuhiro Ogawa, senior manager at Nissan, told reporters.

Also Read : Nissan Note Aura Nismo launched with sporty look, electrified powertrain

Nissan will continue experimenting with larger scale facilities, with an aim to make the process commercially viable in the mid-2020s. "Reducing the use of rare earths is a key challenge as the resources are unevenly distributed, prices fluctuate depending on supply-demand balance, and the mining and smelting process has an impact on ecosystems," Ogawa said.

Nissan, which has been cutting the use of heavy rare earths at the design stage and recycling them, will aim for zero dependence on newly extracted resources in future, he said.

1498.0 cc

1498.0 cc Diesel

Diesel