Nissan develops techniques to speed up production of carbon fibre parts

- The carbon fibre material can be used to make cars that are safer and more fuel efficient.

_1599119784667_1599119789840.jpg)

_1599119784667_1599119789840.jpg)

Nissan Motor Co said on Thursday it has developed techniques that help speed up production of automotive components made from carbon fibre reinforced plastics (CFRP).

The techniques can cut the lead time to develop such components by as much as half, and cycle time for molding by about 80%, compared with conventional methods, the Japanese automaker said.

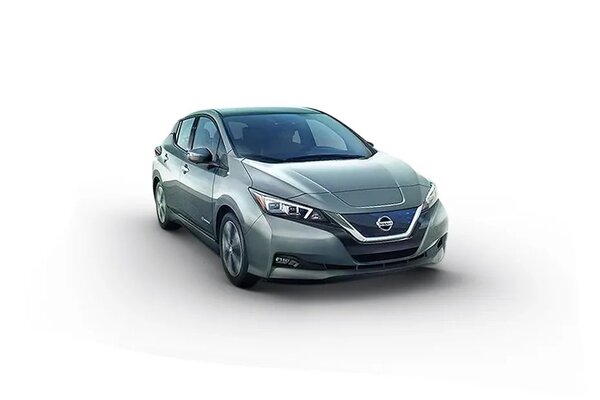

Also check these Vehicles

They involve accurately simulating the behaviour of resin injected into carbon fibre when shaping CFRP components, according to Nissan.

Also Read : Nissan accepting electricity from EVs as payment for parking

The carbon fibre material can be used to make cars that are safer and more fuel efficient. It can also lower a car’s center of gravity when applied to upper body parts, making it more agile and exciting to drive.

Nissan found a new approach to the existing production method known as compression resin transfer molding. This involves forming carbon fiber into the right shape and setting it in a die with a slight gap between the upper die and the carbon fibers. Resin is then injected into the fiber and left to harden.

1498.0 cc

1498.0 cc Diesel

Diesel